During this last year, Noxifer has been developing various accessories to make joints between structural elements, whether metallic or concrete. This is why a new line of products has been created called "Structural elements connection" that includes the PBA Anchor Base Plates and the LOOP-100.

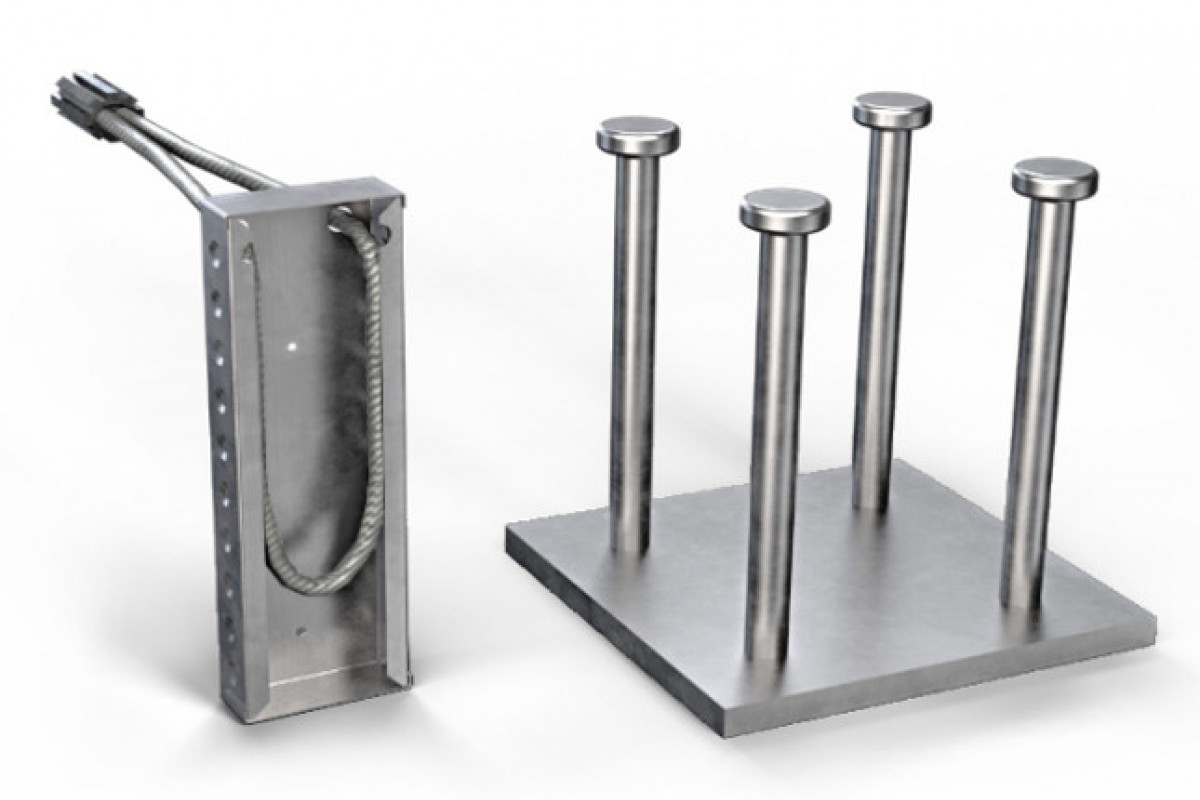

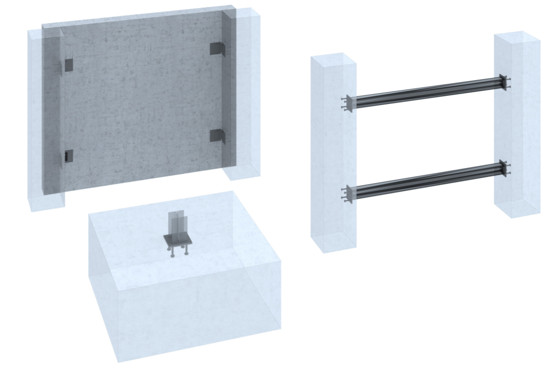

First of all, the PBA Anchor Base Plates are made up of a steel plate on which rigid connectors are welded for insertion into the concrete. These elements are capable of admitting forces and moments in the three main axes.

They are very versatile elements since the dimensions of the plate (base, height and thickness) and of the connectors (length, diameter, quantity and arrangement) can be modified according to the client's needs. Additionally, depending on the degree of exposure, PBAs can be supplied with a primer, zinc, galvanized or stainless finish.

Among its main functions, its use stands out in the connection of metal pillars with the foundation, the retention of panels or creating accommodations to make welded connections.

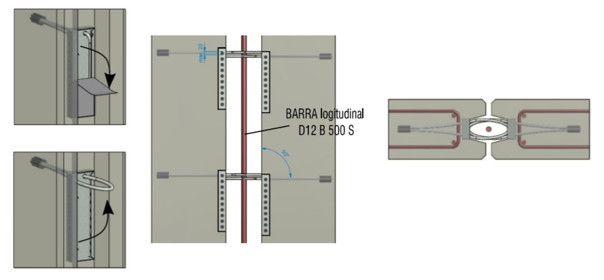

Regarding the LOOP-100, it is made up of a metal box on which a wire is inserted. This wire has two parts, the first is folded inside the box and protected from the concrete filling by a protective tape. The second is stretched to guarantee the adhesion of the LOOP-100 with the concrete element.

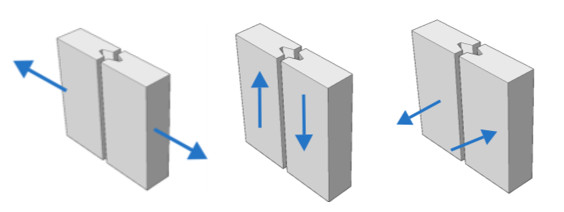

The main function of this accessory is to connect a pillar with a concrete panel or two concrete panels, whether facing each other, corner pieces or another arrangement. In addition, it is capable of resisting forces in the 3 main directions (axial, shear parallel to the joint and shear perpendicular to the joint).

The connection between the panels occurs in a practical and simple way. First, remove the protective tape from the LOOP-100 and unfold the inner part of the wire at a 90º angle. The LOOP-100s of both panels are then criss-crossed and a corrugated bar is inserted along the height of the panel. Finally, the joint is sealed and filled with concrete without shrinkage to make the connection.