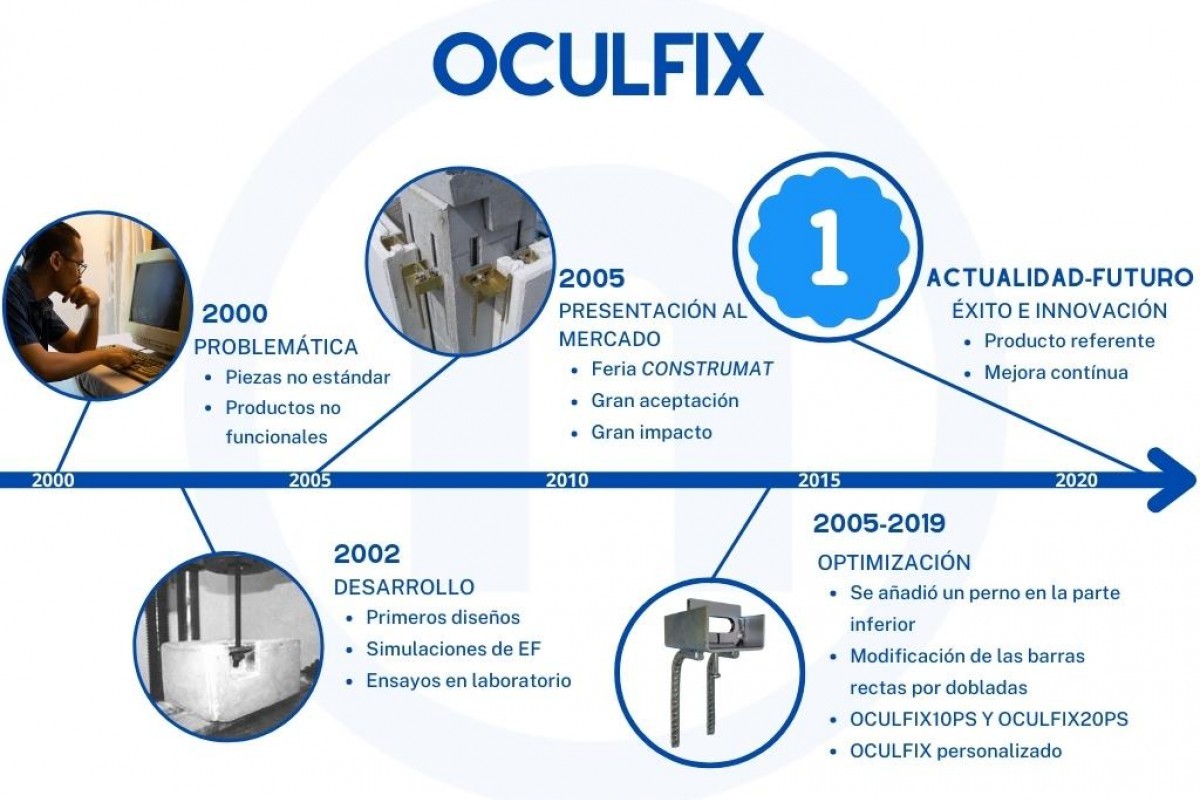

A success story

At the beginning of the 2000s, the retention of concrete panels was carried out through the use of angles that were not very standardized and that remained visible once the assembly of the prefabricated structure was finished. Yes, there was some hidden anchor but, at the time of assembly, it was not fully functional.

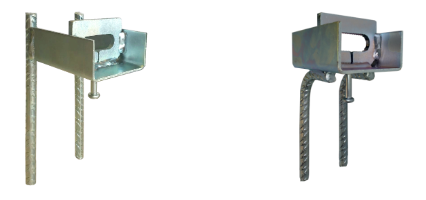

That is why Noxifer developed a standard product adapted to different panel geometries, which will be hidden during assembly to obtain a cleaner finish. This product was designated as OCULFIX.

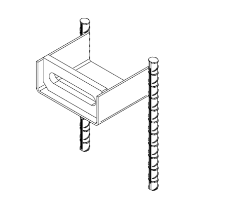

In 2002, the first designs were defined based on the type of loads applied and the thickness of the prefabricated wall. In addition, the type of panel adjustment was also taken into account during the assembly of the panels (OCULFIX 10 – Adjustment through thickness caps/ OCULFIX 20, 30, 40 – Fine adjustment through screws).

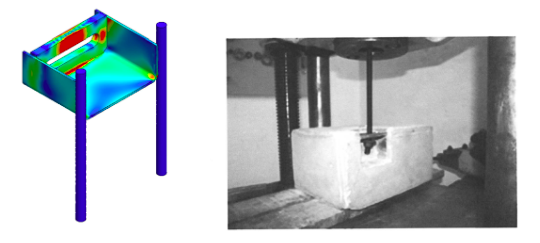

Once the 4 types of OCULFIX were defined, simulations with finite elements were carried out, as well as destructive tests in the laboratory to define the maximum capacities to which the models could be subjected.

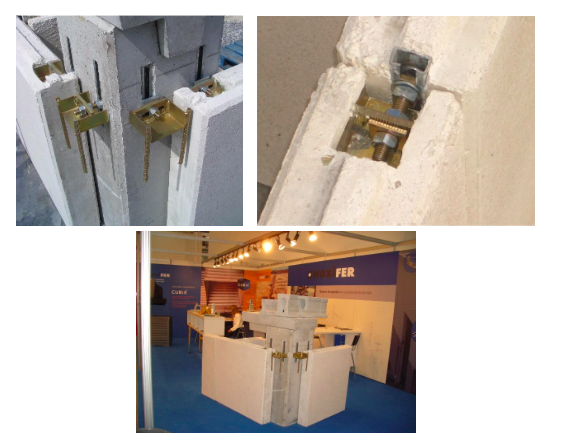

It was at the CONSTRUMAT fair in 2005 when the 4 OCULFIX models were presented to the market, obtaining great acceptance and marking a before and after in the retention of prefabricated panels.

The great success of the OCULFIX over the following years made the technical department continuously innovate different design aspects of the anchor in order to fully optimize the piece and adapt it to different scenarios. In this way, it was intended to obtain a versatile product, a reduction in production costs and thus make it accessible to all customers.

These innovations were carried out between 2005 and 2019 with a first change in the OCULFIX 30 and 40 models in which a shear connector was added at the bottom to increase the degree of connection between the anchor and the prefabricated panel. Later, also in the OCULFIX30 and 40 models, the vertical corrugated bars were modified by ones folded in the shape of an "L" to facilitate the welding process of the part.

In addition, two additional models (OCULFIX10PS AND 20PS) were created to be used in sandwich panels where the position of the corrugated bars was modified to match the concrete part of the panel.

Parallel to the standard models, Noxifer has manufactured models adapted to the requirements of its customers, preserving the original concept of the OCULFIX.

The fact of being up-to-date with the development and update of the OCULFIX has made the product continue to be a benchmark in its field of use and reaffirming its success since its release on the market. But Noxifer does not stop here, but rather continues to modernize its product to make it more optimal and continue to be competitive against other alternatives on the market.